Picking is the warehouse process that picks products from storage in a warehouse to fulfill customer orders. It is the costliest process in the warehouse, comprising as much as 55% of the total work force.

Following are three types of picking process

- Discrete picking – one order at a time

- Clustered picking – multiple orders at a time

- Batch picking – picking all the goods at once to sort to specific customer orders.

Companies may use all three types of picking. With increasing online orders, companies are increasingly installing picking apparatus such as put walls, put-to-light systems, goods-to-person systems and cross-belt sortation systems, to cope with the larger volume of small orders. We will look at these advanced picking methods in another vertical called ‘Automation’.

For now, let us focus on basic picking process, which includes following steps.

- The process commences when operators accept the pick task from Warehouse Management System (WMS)

- System will suggest pick location. Picker to travel to pick location

- Picker to scan location bar code and relevant bar code of goods to be picked

- Once all pick tasks are completed, picker to move goods to packing station

Picking basis handling units

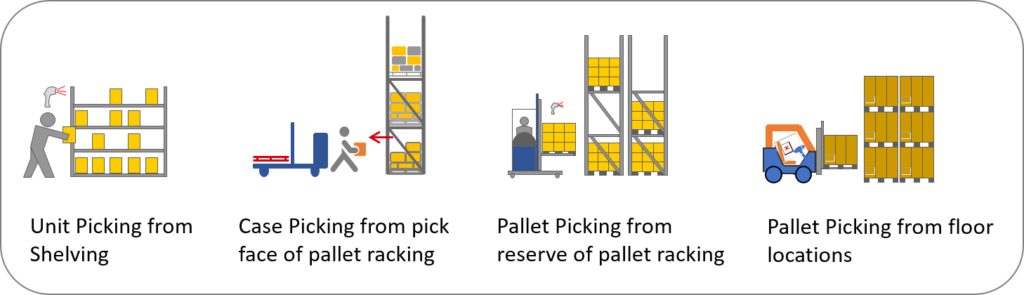

- Unit picking – unit picking is normally done from shelving storage structure.

- Case picking – case picking is done from shelving storage structure, ground location of pallet racking or reserve location of pallet racking

- Pallet picking – pallet picking is done from reserve location of pallet racking or from block stacking.

You deliver some insightful ideas-however I am concerned you might be missing something. I hope to see you add to this, because you are a very eloquent author and I get immense value from reading your posts.

Is anyone able to recommend good Paper and Board B2B Business Data? Thank you 😀

Hi , I do believe this is an excellent blog. I stumbled upon it on Yahoo , i will come back once again. Money and freedom is the best way to change, may you be rich and help other people.

Strong Emphasis on Privacy: CandyMail.org takes privacy seriously, employing state-of-the-art encryption methods to protect user data. When composing an email, the service ensures that all messages are encrypted end-to-end, preventing unauthorized access or interception. Additionally, CandyMail.org does not store any personal information about its users, ensuring their anonymity and providing a secure environment for confidential communication.