Stocktaking or cycle count is when you manually check and record all the inventory at given locations that your business currently has on hand

Importance of stock take

- Track inventory to avoid stock out, overstocking or dead stock

- Stock take can track problems which inventory management system might have missed, such as damaged products, misplaced products or theft

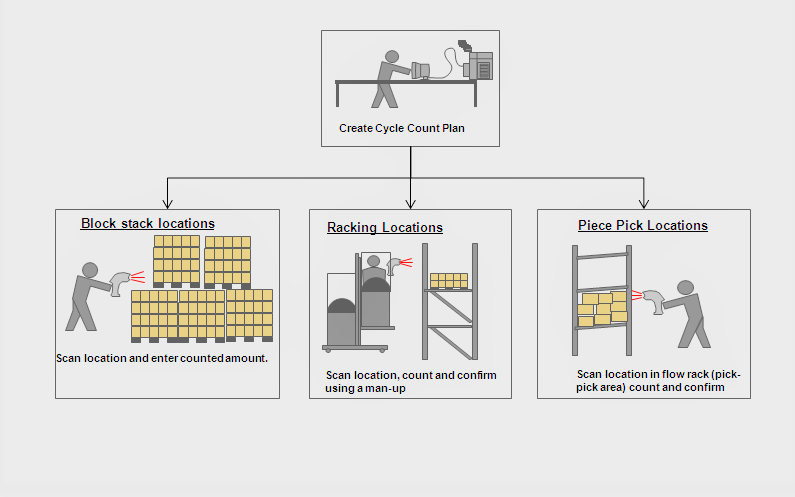

The basic process of stock take

- Go to the location

- Scan location

- Scan SKU

- Count number of SKU / or scan all units

- Enter quantity in ‘handheld device’ / no need to enter quantity if you scan all units

- Confirm task complete

Two types of stock take

Perpetual stock take (PST) or cycle counting is a stocktaking method which involves checking a section of your inventory regularly on set days. It means, instead of conducting a single annual stock take of the entire warehouse, it is broken down into several smaller mini stocktakes.

PST brings several benefits over annual stocktaking, the biggest one is disruption to warehouse operations is being avoided.

Annual Stock take or Annual cycle count is Stocktaking when you manually check and record all the inventory at given locations that your business currently has on hand, once in a year. Annual stock take requires warehouse operations to be stopped during stock take process.

Dealing with stock discrepancies

Any stock discrepancy is not a good news for your business, even if you discover that you actually had more stock on hand than you thought. They’re often symptomatic of a larger problem in warehouse inventory control which might be catastrophic if left to fester. Plus, they mean you are running your company on incorrect information.

Once you know what caused the discrepancy, first step is adjust to correct inventory number at the same time take steps to ensure that it doesn’t happen again. This may require changes to your processes, new software or extra security. Then, simply upload the new correct figure into your system to resolve the problem.

Great beat ! I wish to apprentice while you amend your web site, how can i subscribe for a weblog website? The account helped me a acceptable deal. I had been a little bit familiar of this your broadcast offered shiny clear concept